The following checks will require you to have acces to the underside if the car.

Vehicle Structure

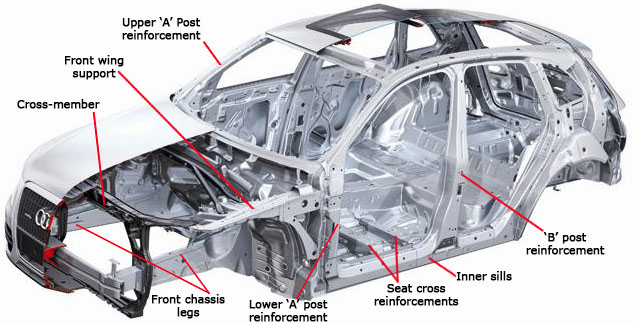

The checks on vehicle structure are dependent on the original design and construction of the car, and whether certain parts are load bearing or not. Also, any area within 30cm of a safety related item will also be checked, plus any part which is deemed to be playing a role in supporting the vehicle as a whole and which is corroded or damaged sufficiently to hinder the safe operation of steering, suspension or brakes.

Check all main sections of main body of the vehicle including subframes and crossmembers. Excessive corrosion, damage or inadequately carried out repairs are likely to result in a fail.

If you find surface rust, this shouldn't cause a fail - only items that are 'corroded to excess'. Using a screwdriver, prod the rust. If a hole appears the rust will need to be repaired or the item replaced. The tester will also push the rusted area to test it for give. If there is too much give, the car will fail. Good steel should be completely firm under pressure and ring cleanly when struck with the screwdriver handle, rotten metal will creak. The tester will use this to test any areas where he suspects that filler or a similar product has been used to cover up corrosion.

The image, right, shows a rusted inner sill. It has been marked with a yellow crayon, which is used by many testing stations to highlight a defect.

If the steel is damaged, either from an accident, an improper modification, or from fatigue, the car will fail. Any cracks or tears in the steel should be easy to spot, and would cause a fail. Check all welded joints to make all are still sound.

Check the front chassis legs, which should be joined to the bulkhead and run along both sides of the engine bay, before joining a front crossmember. They should be in good condition and soundly secured. Examine the inner wings paying close attention to the suspension struts. If there is a separate subframe then check this, too. There should be no corrosion, or any within 30cm of its mounting points to the main body.

Check the floor, especially around the joints to the inner sills, the inner sills themselves, and the seatbelt and handbrake mounting points.

At the rear of the car, check the suspension mounts and the area around them, and spring hangers, and/or subframe mounts.

Under The Bonnet

This area must be free from 'excessive corrosion' and be structural sound. Pay special attention to:

The inner wings, especially the area around the front suspension mounting tops. Look for signs of rust and for signs of distortion that may indicate corrosion.

The bulkhead, as this can suffer damage and corrosion from blocked drain tubes, so closely examine steering or braking component mounting points.

If it is visible, check the top surface of the front crossmember under the radiator, as well as its joints to the inner wings.

Inside the Boot

Pay special attention to the suspension mounts, the metalwork of the inner wheel arches, and the boot floor - the edges of which are most likely to rust first.

Structural Repairs

If the structure has had patch repairs then they must adequately replace the strength lost through the damage or corrosion, and should be welded completely around their circumference - unless they are at a panel edge which was spot welded by the manufacturer originally, in which case stitch welds are acceptable. No other form of repair will pass the test.

External Steering System - Rack and Pinion

Check the entire length of the steering column. If possible, examine the coupling or join to the steering rack.

The rack mountings and rubber brushes (where fitted) should be checked for security and deterioration. There should be no leaking oil or grease.

Power Steering

The power steering fluid must be above the minimum level marked on the reservoir. The pipes and hoses must not be excessively corroded or damaged, and must not catch on any other part of the car.

The power steering ram and its housing must not be damaged, and there must not be excessive play at the anchorage point.

The power steering pump and its drivebelt should be checked for condition and security, both must be securely mounted.

Any repairs or modifications to the power steering which the tester considers to have had an adverse effect on the steering will result in a fail.

For electronic power steering, if the Malfunction Indicator Light illuminates on the dashboard to signify a problem with the EPS, then the car will fail.

Front and Rear Suspension

Check that there is adequate clearance between the chassis and any bump stops that are fitted. If, due to weak springs, any part of the body touches the wheels when loaded, then the car will fail. If you detect this, new springs will be required.

Where the suspension or its mounting system, such as a subframe, meets the body (and within 30cm of that point), look for any corrosion, distortion or fracturing which significantly reduces the original strength of that component. Any previous repairs must have adequately replaced that strength.

Check front coil springs and their locating seats for cracking or corrosion. If the functioning of the spring is impaired, or if the end doesn't locate properly, the car will fail. Any damaged spring will need to be replaced.

Leaf springs and their mounting eyes must be in good order. If their action is impaired in any way, the car will fail, and there should be no contact between the leaf and the body. The only movement allowed in the spring mounted pins is 2mm for a 12mm pin, and 3mm for a 25mm pin. The eye brush will fail for similar play due to deterioration. Side-to-side movement at the mountings must not exceed 6mm. The mounting plates must be free from cracks and other damage including excessive corrosion. Mounting bolts must all be present and tight.

All associated components will be checked - wishbones, radius arms, subframes, anti-roll bars etc. All these parts and their mountings will be checked for missing fittings, wear, rust,and other damage. Mounting brushes and pins will fail if there is sufficient deterioration to allow excessive movement, as will any rubber mounts in the same condition. The same for ball joints which allow excessive movement.

Wheel Bearings and Suspension Joints

With the car safely raised, gently spin the front wheels and listen for any noise which may indicate roughness in the wheel bearing. Also try turning the wheel using just a finger tip, as this may allow you to feel the roughness.

Hold the wheel and try to rock it. If you detect play, you will need to investigate further. Ask someone to apply the brakes, and then rock the wheel again. If the play disappears, then the cause of the rocking is likely to be the wheel bearing. If the play continues, the suspension joint is probably the cause.

If the wheel bearings aren't responsible for the play, hold the wheel at the top and bottom and rock it once more. If you can, while you do this (if you can't ask someone to help) peer round the wheel and examine the top and bottom ball joints, the inner mountings of the wishbone/bottom suspension arm, ball joints and inner brushes.

The rear wheel bearings can also be checked this way.

CV Joints/Boots

The driveshaft will be checked for distortion and damage. To check for distortion, turn the driveshaft fully, any distortion should be easy to spot as the driveshaft will appear to rise and fall. If it is bent, the car will fail.

If the driveshaft passes through any support bearing, take hold of it and lift it up and down while looking for any signs of play in the bearing or housing mountings. Excessive play will result in a fail.

Turn each wheel onto full lock and slowly turn it, checking the pleats of the CV joint boot for damage or insecurity resulting in leaks. Like the suspension ball joint boots, if dirt can get in then the car will fail.

Shock Absorbers

These will be tested for signs of leakage. If any leak is particularly bad, it probably means the seal has failed, and so the car will fail the test. Mounting pins and bushes will be checked for deterioration and excessive play. If the suspension unit is rusted to the point where its operation is compromised then it will have to be replaced.

Exhaust System

The exhaust system must be adequately supported. It will also be tested with the engine running to make sure that there are no leaks. Any leak, which didn't affect the catalytic converter, would have to be fairly large in order to cause the car to fail. Leaks can often be identified by a trail of black carbon which emerges from any hole.

If you need to repair any leaks, the repairs must be durable, completely fix the leak, and must result in the system as a whole remaining structurally sound. Some exhaust boxes are factory fitted with a small hole drilled at the lowest point to allow accumulated water from condensation to drain away, and so will not cause a fail.

The level of exhausted noise must not be louder than that normally expected for a similar car in 'average' condition. If it is louder, the car will fail.

The silencer tailpipe must be far enough away from the body to prevent fumes entering the interior.

Fuel System

All supply and return pipes will be checked for damage, with and without the engine running. The lines must be properly secured to the body. The filler cap and neck will be examined for spilt seals or any other damage or deterioration that could result in a fuel leak.

If the petrol pump and/or the fuel filler is visible to the tester they will be checked for leaks and security of mounting. The fuel tank will be checked for corrosion or damage to its mounts.

Engine Mounts

These will be examined for security and signs of excessive movement or for deterioration. Any missing mount will cause the car to fail. Mounts to the gearbox found on front-wheel cars will also be examined.

Brakes

All calipers will be checked for leaks. With the brake pedal down, check the calipers for signs of fluid loss. Any such loss will signify a leak and result in a fail.

With the pedal still down, check the flexible brake hoses for signs of bulging and swelling, as this will indicate blockages inside the hoses. Also check these hoses for deterioration, cuts or any other damage. The hose shouldn't be kinked, must be attached to its mounts correctly, and mustn't touch the body or wheel.

The brake discs must not be heavily scored or rust damaged. If the pads can be seen they will be checked for the amount of wear remaining. If they have less than 1.5mm of friction material left, the vehicle will fail. Mounting bolts and/or securing pins will be checked for presence and security, including locking nuts or pins.

The metal brake lines that run down the underside of the car will be checked for rust and damage, and that they are securely mounted to the body. Light surface rust shouldn't cause a fail. With the brake pedal down, check all unions for leaks.

All brake pipe connections should be leak free.

If the car has rear drum brakes, check the brake pipe-to-wheel cylinder join for leaks; staining here will expose any leak.

A brake performance test is carried out on brake rollers at the test centre. This is not something that can be replicated away from the test centre. However, as long as your brakes have been well maintained, and services at correct intervals, there should be a problem.

Emmissions

Without specialist equipment it is impossible to replicate the emissions test. However, to help your car pass this part of the MOT, you should make sure it has a regular service and that worn sparkplugs and dirty air filters are changed.

If excessive black or blue smoke is emmitted from your exhaust, then the car is likely to fail the test.

After The MoT Test - Advisory Notes

On the MOT pass certifiace you may find a series of advisory notes. It is wise to pay attention to them, as they will identify any problems that, although not serious enough to cause a fail this time, may result in a future MOT fail or even a breakdown.

Re-Test

If you car fails on any of the items listed below, then as long as they are repaired and the car re-submitted before the end of the next working day, the items can be re-checked free of charge. If you leave the car at the test station to be repaired, a partial re-test will be carried out and you will not be charged a re-test fee.

If you take the car away then return it to be re-tested the next day and it then fails on any other item not on the list below, a re-test fee of up to half the amount set by VOSA for a full test may be charged to you, as long as the car is returned within ten working days. If the car isn't returned within this time, a full test will be required once more.

Back to Part 1 - The Easy MoT Home Checks